Liebherr electric cranes ordered for SAL-Jumbo Orca newbuilds

SAL Heavy Lift and its alliance partner Jumbo Maritime have placed an order for eight all-electric Liebherr heavy lift ship cranes for the new generation heavy lift Orca Class vessels. Alliance’s order at the Wuhu Shipyard in China includes four firm vessels and an option for additional two.

As part of the Orca project, two cranes will be installed on each of SAL’s four vessel newbuildings. By combining the capacity of both cranes in tandem mode, cargoes of up to 1,600 tonnes can be handled. The innovative ship cranes will make it possible to lift components of the future project cargo while being prepared for the increasing environmental protection requirements.

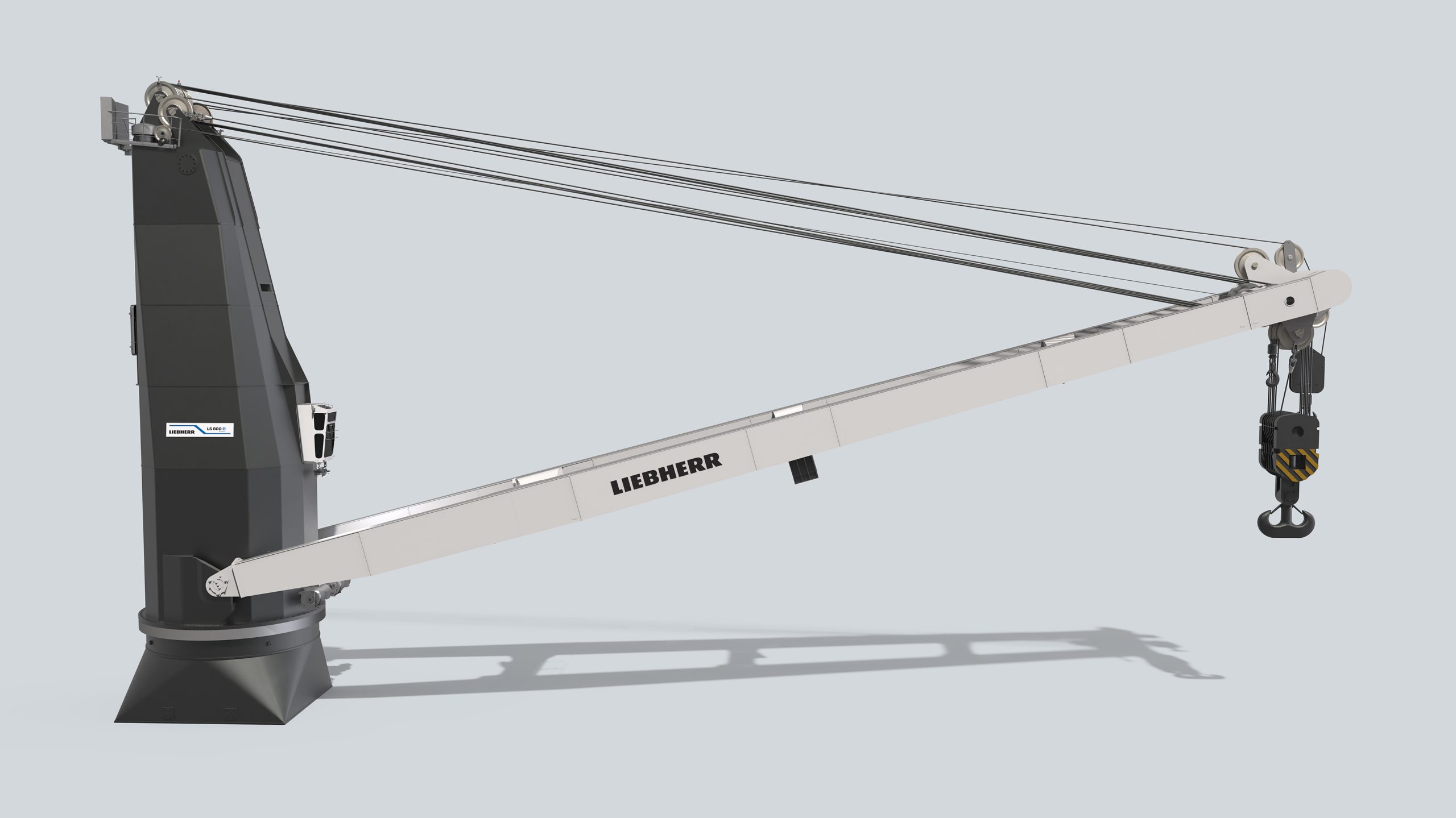

The LS 800 E is the latest innovation of Liebherr’s heavy lift ship crane portfolio. The recently launched crane is designed for the ever heavier and larger cargo. Moreover, the all-electric drive concept supports vessel operators in saving CO2 emissions.

The order of the first LS 800 E ship cranes marks the beginning of a new phase in the long-term partnership between the Harren Group and Liebherr. At the same time, it is SAL Heavy Lift’s first newbuilding project with Liebherr. The two family-run companies have been cooperating since the start of this new project for four multipurpose heavy lift vessels. The crane manufacturer was actively involved in the development from day 1. Since the Orca class of ship breaks new ground in many respects and will significantly raise the bar in the relevant transport segment, the crane developers were also challenged to rethink many details in addition to general requirements, and performance parameters and to make their contribution to the efficiency and innovation of the ship concept. The result is a perfectly coordinated unit of crane and vessel that enables maximum efficiency and performance.

All-electric energy efficiency

Apart from fulfilling the demanding operational requirements and different cargo scenarios, the new Liebherr Ship Cranes enable significant savings in smart interaction with the innovations on the ship side. The new LS 800 E actively communicates with the ship’s power management system and thus enables intelligent energy utilisation. Recovered energy is fed back into the ship’s energy system and stored so that it can be released when energy consumption is high again. This leads to a noticeably reduced fuel consumption and a considerable reduction of CO2 emissions on the Orca ships. The entire power electronics of the drive system are installed inside the cranes. This allows the limited space below deck to be used for other purposes and noticeable facilitates the integration of the crane into the ship’s design.

Compact design for high durability

The integration of the entire drive concept inside the crane also significantly increases the durability of the components, as they are protected from the weather. “The reliability of the cranes is extremely important for heavy lift vessels. They must function for the entire life of the vessel. The family-run company Liebherr offers a convincing overall package for this, thanks to its wide-ranging product and technology knowledge as well as its worldwide service network”, explains Martin Harren, CEO of the Harren Group.

Ready for future requirements

The LS 800 E ship cranes expand Liebherr’s product portfolio and enter a new segment. They are the largest ship cranes Liebherr has built to date. The cranes are aimed for a growing market of shipping large wind industry components. In the future, these will not be manageable with the lifting capacities and dimensions that have been common in the market so far. Moreover, the supply of heavy lift vessels with cranes of 800 tonnes capacity is lower than the expected future demand. Liebherr has claimed the resulting growth market for itself with the development of the LS 800 E ship crane.

The all-electric drives are already preparing the cranes for future environmental protection requirements in terms of energy efficiency an emissions regulation. “The development of the new cranes combines SAL’s user experience and Liebherr’s crane construction expertise. The LS 800 E will be the most advanced ship crane in its segment”, comments Gregor Levold, General Manager Sales for Liebherr Offshore, Ship and Port Cranes. “The all-electric heavy lift cranes feature a variety of innovations that simplify maintenance and reduce operating costs. At the same time, they are characterised by innovative as well as environmentally friendly drive technology”, adds Levold.

At what radius can the 800 tons LS800 lift the 800 ton load?