K Line opts for unconventional approach in first 2022 project cargo shipment

RoRo shipping companies are getting more and more request to move project cargo and K Line is no exception. For the latest shipment, K Line was requested to transport a 100-ton reactor on its Sirius Highway from Europe to the United States, the first heavy piece of the year 2022.

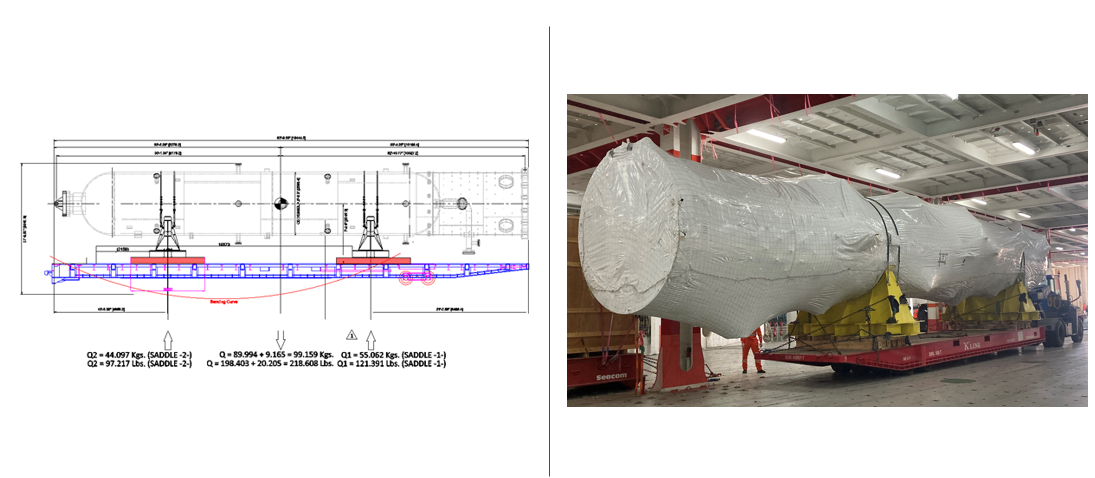

While the project may not look complex at first sight, K LIne noted that the technical preparation and realisation of the specific cargo requirements constituted an interesting challenge. Based on the dimensions, footprint and weight of the cargo exceeding the limits of a 62 ft standard roll trailer, the choice was to use a K Line unique roll trailer design, which is suitable for such kind of loads.

One option for consideration was to spread the load on two resting points with more than 3-meter-wide beddings. However, this idea was technically contentious and comes with the problem of too much wooden dunnage being involved, which is unfavourable in many regards.

K Line avoids building Jenga towers with unconventional solution

To avoid the option of building a “Jenga” wood tower beneath the cargo K Line decided to choose an unconventional option with a 40 FT heavy duty MAFI type. This K Line unique roll trailer design can accommodate higher point loads due to massive side beam constructions. To make this plan work on a 40 FT MAFI K Line had to increase the distance between cargo saddle and MAFI to create the required clearance above the gooseneck of the tug master.

With that small modification K Line finally managed to fit the saddle within the reinforced areas of the 40 FT RT which allowed a max trailer load of 97 percent in regards of bending incidents.

Also, by lifting the cargo position with dunnage K Line not only created clearance above the gooseneck, but also took care of additional clearance for the challenging ramp approach created by cargo overhang of more than 4 meters on the 40 FT MAFI.

Cargo securing and lashing was the least problematic part of the shipment as the cargo was equipped with sufficient lashing points. All lashings were done as per IMO CSS ANNEX 13 standards to withstand the current weather condition on the Atlantic Ocean.

You just read one of our premium articles free of charge

Register now to keep reading premium articles.