Construction starts on Siemens Gamesa-committed Orca newbuilds

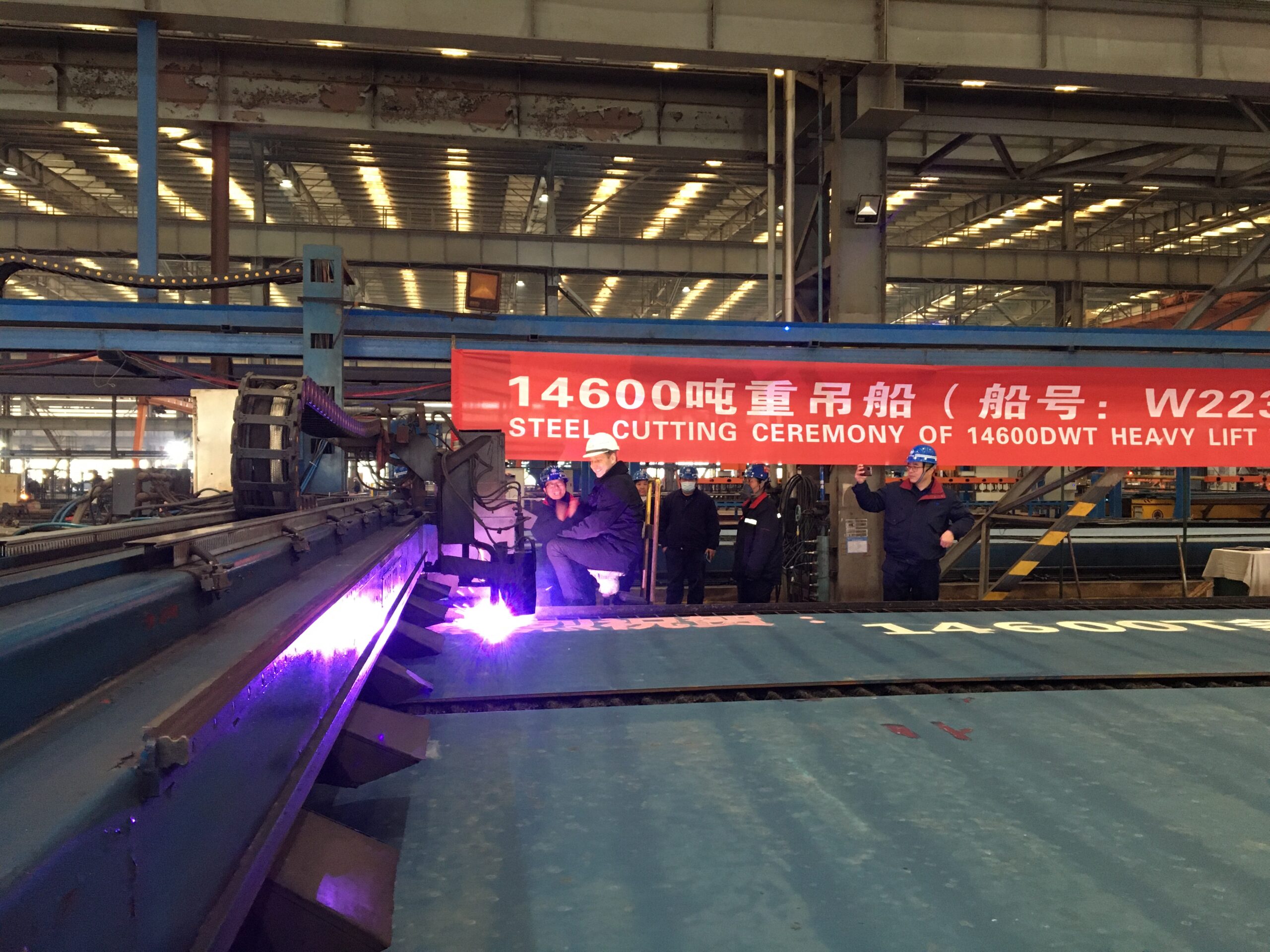

Following a long and extensive planning phase, the construction of the Orca newbuilding series for the Jumbo-SAL-Alliance, kicked off. SAL Heavy Lift and Jumbo Maritime said the first steel was cut at the WuHu Shipyard in China on March 22, for the first vessel, currently named W2231.

The alliance members noted that the expected delivery date for the first vessel on July 5, 2024. The steel cutting for the second vessel in the series, W2232, is scheduled to take place this week already, with the keel laying following in the near future.

Newbuilds committed to Siemens Gamesa

The first two ships will be exclusively involved in the transportation of offshore wind turbine components in a long-term commitment with Siemens Gamesa Renewable Energy, the alliance said in an earlier statement.

Two additional sister vessels will enter the premium heavy lift shipping market to serve the clients of the Jumbo-SAL-Alliance in the first half of 2025.

Orcas fit for the future

The vessels measure 149.9 metres by 27.2 meters and provide a capacity of 14,600 dwt. Despite their compact outer dimensions, the vessels have a box-shaped single cargo hold with the largest dimensions in its class. Provided the hatch covers with a capacity of 10 t/m² are not utilised for stowing super-heavy deck cargoes, such as 3,000 ton cable carousels, the vessels can accommodate over-height cargo in the hold and sail with open hatch covers up to full scantling draft.

The vessels will also feature Ice class notation 1A, a Polar Code certification and the reduced design temperature of the hull and equipment allow the ships to safely operate in cold conditions as well.

Two 800-ton Liebherr cranes specifically designed for this ship type can handle cargo items weighting up to 1,600 tons in tandem. The vessels will also feature Wärtsilä hybrid propulsion system.

You just read one of our premium articles free of charge

Register now to keep reading premium articles.