Heerema develops floating wind turbine installation method

Heerema Marine Contractors has signed an agreement with Parkwind and MHI Vestas for the first floating wind turbine installation. The newly developed method will simplify the installation of offshore wind turbines at sites where the soil does not allow the use of jack-up vessels.

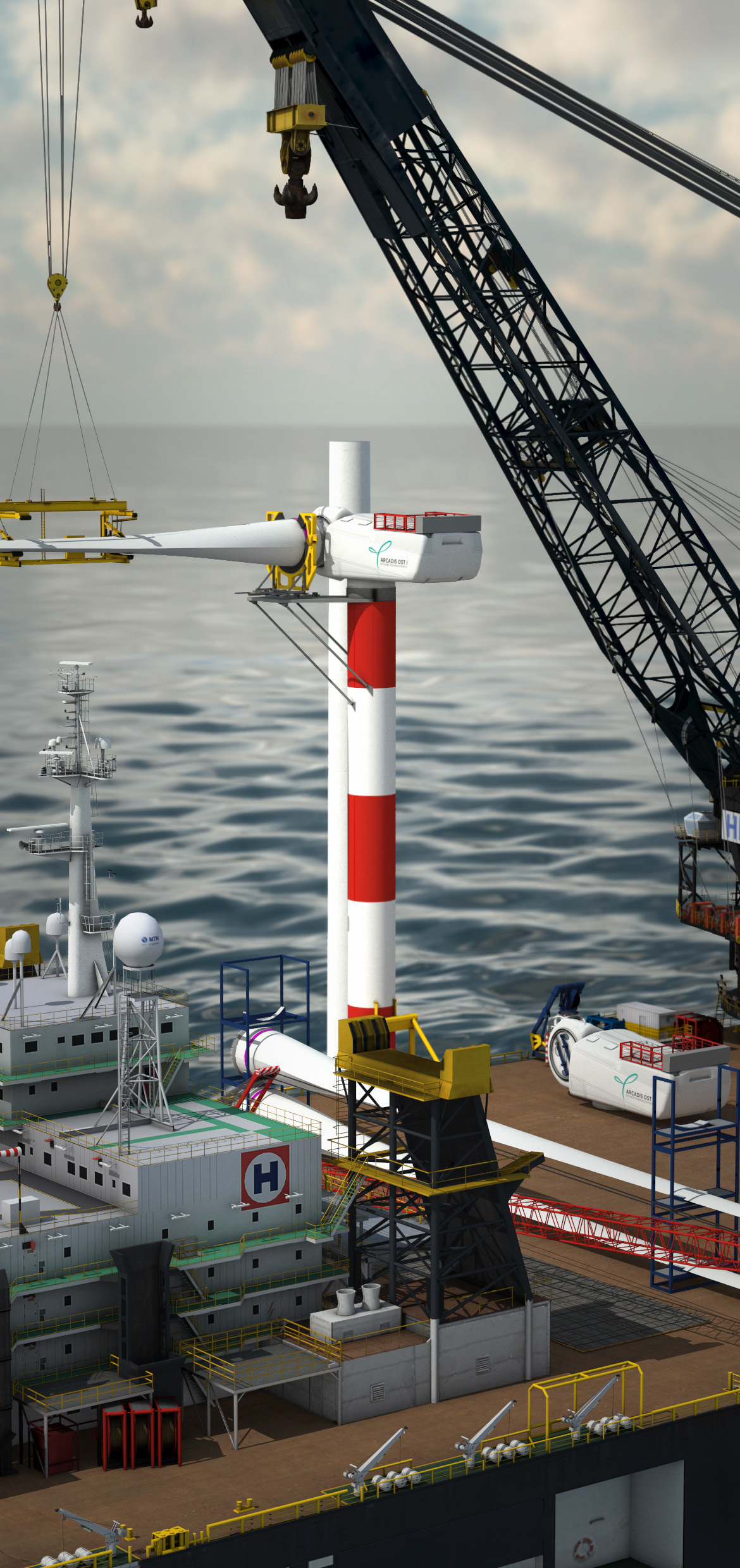

Heerema will use the floating method for the construction of Parkwind’s 257 MW Arcadis Ost 1 offshore wind farm, located 20 kilometres northeast of the island of Rugen in the Baltic Sea.

Because of the challenging soil conditions at the Arcadis Ost 1 site, Parkwind looked at possible alternatives to traditional installation methodologies. Together with Heerema Marine Contractors and MHI Vestas, the floating installation method was developed.

The main advantage of floating installation is that all interaction with the soil can be avoided, reducing the project’s risk compared to traditional jack-up installation and allowing for faster operations, Heerema states.

The developed method is based on utilizing a floating installation vessel to assemble the wind turbine components. The vessel will have all turbine components on its deck including a dummy tower. This tower will provide a stable platform onboard the vessel to assemble the nacelle and the blades.

The first step will be lifting the wind turbine generator tower onto the pre-installed turbine foundation. The second step includes lifting the nacelle onto the dummy tower and attaching the blades. After assembling the nacelle and rotors, the complete top part of the wind turbine will be lifted onto the tower in one piece.

“Taking the turbine installation based on a floating vessel from theory to practice is a major step forward for the offshore wind industry”, says Parkwind’s co-CEO Eric Antoons. “We saw this as the best solution for our German Arcadis Ost 1 project where soil conditions are challenging.”

The development of the method took over a year and included visualization of the local situation in Heerema’s simulation centre, where the company studied the impact of crane and vessel controls, realistic weather conditions, sea swell patterns and seabed conditions.