Fred. Olsen joins competitors in crane capacity expansion

Fred. Olsen Windcarrier becomes the latest offshore contractor to invest in bigger cranes in anticipation of the new generation of wind turbines that are set to hit the market in 2021. The company has ordered a 1,600-tonne leg encircling crane with Huisman Equipment which will be the tallest in the market.

The new crane will be installed on one of Fred. Olsen’s Gusto 9000 jack-up vessels, but the company did not say which one. The offshore contractor has two these vessels in its fleet, the Brave Tern and Bold Tern. Both vessels are currently equipped with an 800-tonne Gusto main crane meaning the new crane will double the lift capacity of one these vessels.

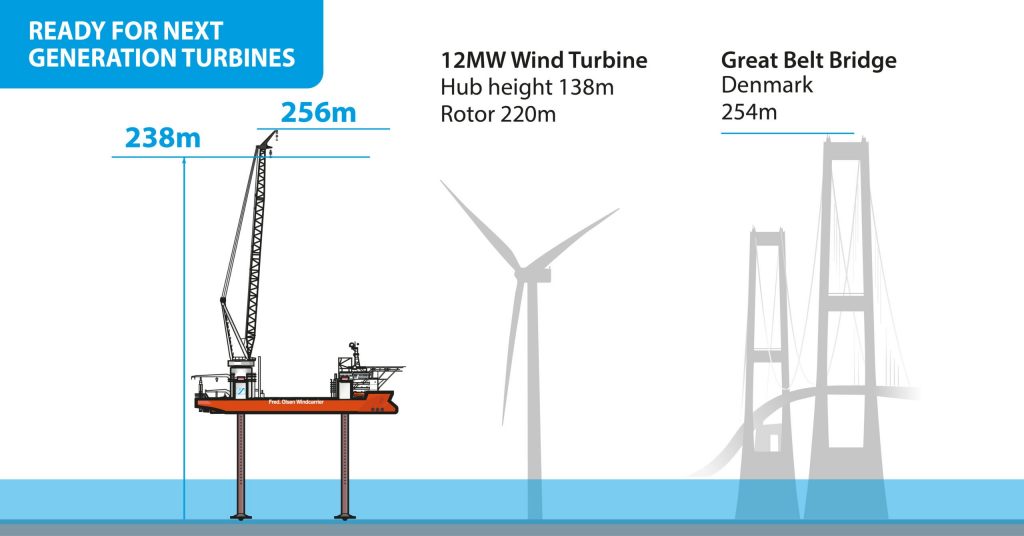

With the upgrade, the vessel will be able to lift loads on its main hook up to 238 meters above the seabed. This height includes the full extension of the support legs and the vessel’s hull. The crane itself will be able to lift loads of 1,600 tonnes up to 105 metres above the deck and loads of 1,250 tonnes up to 155 metres.

These new capabilities give the vessel sufficient power and reach to install the latest generator of wind turbines, GE’s 12 MW Hailade-X. The hub of these generators sits at 138 metres above the seabed while the rotors reach up to 220 metres.

“With this new crane, we are gearing up for the next generation of offshore wind turbines. After installing more than 600 offshore turbines, we continue to set our sights higher and higher, knowing that our clients need a partner who can support them in establishing tomorrow’s offshore wind gigaparks”, says Even Larsen, CEO at Fred. Olsen Ocean, the parent organization of Fred. Olsen Windcarrier.

“This unique crane has been enhanced with an even more extreme boom and outreach capacity”, adds managing director Alexandra Koefoed of Fred. Olsen Windcarrier. “The crane allows us to stow the wind turbine components in a more flexible way despite the increased crane weight, thus maintaining or exceeding the payload we carry for our clients.”

The blades of the wind turbines can be installed with the crane auxiliary hook which is faster, can operator in higher speed winds and lift loads of 400 tonnes even higher up to 165 metres above the deck. “All together this is a considerable lifetime extension for the vessel, as the weight and dimensions of wind turbine components continue to increase”, says Koefoed.

Trend

The announcement of the 12 MW Haliade-X has sparked a clearly visible trend among the offshore contractors. Most major players have either ordered new cranes, like Fred. Olsen and Swire Blue Ocean, or entirely new installation vessels, like Jan de Nul en DEME.

DEME currently leads the way in terms of sheer lift capacity, ordering a 5,000-tonne main crane for its new offshore installation vessel Orion, while Jan de Nul has ordered a new installation vessel with a 3,000-tonne main crane.

Other companies, like SAL Heavy Lift, have engineered jib extensions to increase the reach of their cranes. Almost all upgrades and new build orders are said to be made in anticipation of the larger and heavier offshore wind components.

You just read one of our premium articles free of charge

Register now to keep reading premium articles.