New Tetrahedron crane can increase lift capacity of existing jack-ups

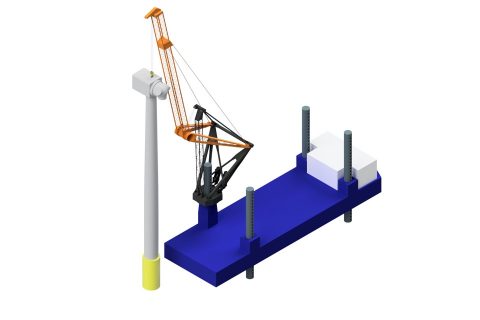

Tetrahedron has designed a new crane for the installation of next-generation offshore wind turbines. Based on a fundamentally different motion principle and an efficient structural load transfer, the crane lifts higher than alternatives and can fit in the same crane footprint.

Existing jack-up vessels often cannot lift high enough to reach the highest parts of the latest 10-14 MW class turbines. If owners are unable to increase their lifting height sufficiently, their ships are at risk of becoming unusable within the offshore wind industry by 2023.

The new crane offers an economically viable path for owners who want to upgrade jack-ups or build more cost-competitive units to compete in the turbine installation market. The design is future-proof, even for future turbine developments up to the 20MW class. The innovative crane can be retrofitted onto existing jack-ups easily, delivering a competitive upgrade in lifting height and allowing existing vessels to compete well into the next decade.

No hull re-enforcement

Founder and Director Wilco Stavenuiter says: “Due to its unique design and patented technology, the Tetrahedron crane simply lifts 50 metres higher than existing cranes, without adding any weight or complexity. In practice, jack-ups that are originally designed to install 5-MW turbines can be upgraded without hull re-enforcement (due to the low moment a Tetrahedron crane exerts on the jack-up) and will be able to install future wind turbines such as the SG 14-222 DD or the GE Haliade-X.”

This drop-in solution on existing jack-ups unlocks additional earning power. As an example, the Tetrahedron 45 can lift a Haliade-X nacelle at 40 metres radius, 180 metres above the waterline with sufficient clearances to install the blades, while still fitting on smaller jack-ups with minimal modification.

Joint development

Offshore installation contractor Van Oord, Delft University of Technology and various industry suppliers have contributed to the development of the crane in collaborative projects co-funded by the Netherlands Enterprise Agency (RVO). The concept design of the crane is completed and verified by DNV GL and now Tetrahedron focusses on crane delivery in Rotterdam by 2022.

This article first appeared on SWZ|Maritime, a sister publication of PCJ.

You just read one of our premium articles free of charge

Register now to keep reading premium articles.