Heavy lift challenges push Roll Group into new investment

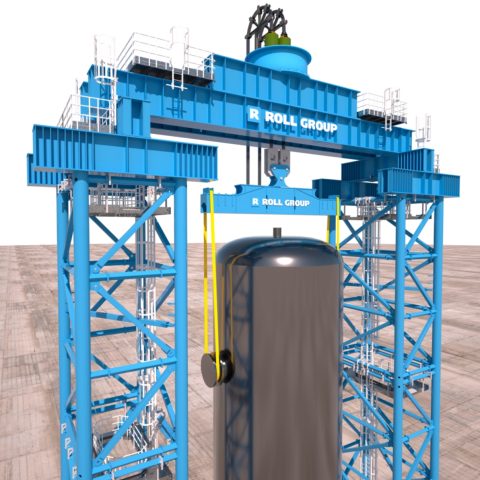

Plenty of projects require heavy lift operations when certain modules and pieces of equipment need to be set into position. Heavy lift operations are also accompany the complete factory-to-foundation transport of project cargo. In order to tackle heavy lifting challenges and boost its own capacity, Roll Group has invested in a large gantry system.

The gantry system is being fabricated currently and the company expects it to be operational mid-2023. The company already has experience with smaller systems, however, the investment is allowing the company to enter a new tier in the heavy-lift market.

“With this gantry system we can further grow in the heavy lift industry as this system will allow us to enter the market of the bigger land-based projects as the gantries are often combined with crane and SPMT scopes,” Roll Group’s CEO, Peter Rondhuis, explains.

Rondhuis further noted that the investments enables Roll Group to offer a full factory-to-foundation solution by combining our fleet of heavy transport vessels, SPMTs, cranes and gantry systems. “This reduces overall risks for our clients and provides a single point of contact for the whole operation,” he said.

Fit for various markets

The gantry system consist of various components that can be fitted together in various configurations. With the flexible and robust design, the height, width, capacity, and shape can be varied to match the project. Therefore, the final construction can be adjusted to suit the client’s project, Roll Group noted in its statement.

The gantry system will be fully Lloyds certified in design, fabrication and testing to match with Roll Group’s safety and quality standards.

The system can be used in various markets, the company added. For its initial project in the Petrochemical industry it can be used for the installation of tall reactors, over 100 metres in length, with a weight of over 2000 tonnes without the use of external guy wires.

In the renewable market, the system can be of use for the integration of jackets or the load out of offshore wind floaters. Further, the system is ideal for the installation of goliath cranes, as the temporary support structure for modules or bridges during transport or weighing, as the heavy support for weighing of offshore modules and much more.

You just read one of our premium articles free of charge

Register now to keep reading premium articles.